PVP - Innovation drives Quality.

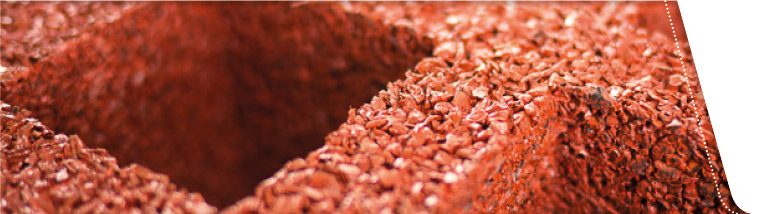

Welcome to PVP Triptis GmbH – a German manufacturer that is known as a specialist for developing and manufacturing products made of rubber granules, combined with polyurethane.

PVP Triptis GmbH is the only manufacturer worldwide that handles the entire process chain from granule manufacture to the finished end product.

Our granulation business unit produces approx. 18,000 m. tonnes of rubber powder and granules annually. Currently more that 1.4 million square metres of our products PROTECTMAT (building protection), ACOUSTICMAT (noise control), SPORTMAT (sports and equestrian as well as artificial turf) and TRANSMAT (transport locking) are sold in the form of rolls, mats and moulded products worldwide.

Thanks to the constant growth over the past few years, the company and its location continue to offer development potential in line with market requirements. With our technology in rubber - Made in Germany - we satisfy the highest quality standards in accordance with DIN EN ISO 9001: 2015, DIN EN ISO 14001:2015 and DIN EN ISO 50001:2018. The wide variety of products and services we offer demonstrates a high degree of technical competence and innovation. Together WE are able to make a sustainable contribution to preserving the environment and conserving resources while implementing the most stringent quality standards at the same time.

We produce our own rubber granules using our own machinery. Our end products include rubber mats, moulded rubber parts and sports surfaces with a wide variety of compositions and are an integral part for a wide range of applications.

Our family-owned company, PVP Triptis GmbH, was founded in 2003 and is a growing partner for industry, construction, sports and recreation. Our products offer a wide range of uses for YOUR needs; from rubber powder and rubber granulate to finished final product. As a recycling enterprise and authorised special waste management firm, we produce our raw materials according to the latest standards and are also certified in accordance with DIN EN ISO 9001:2008 and DIN EN ISO 14001:2005. We understand and are aware of our duties as a manufacturer of secondary raw materials under the REACH EG/1907/2006 regulations.

The raw materials we produce render a sustainable contribution to environmental protection and maintenance of our habitat.

We are the only enterprise worldwide that has a continuous production chain and thus is in a position to quickly react to YOUR requirements. There is a wide variety of granulate types available from raw material we produce ourselves according to the mechanical, ambient grinding process. Moreover the customer-oriented, manufacture of granulate types for the most diverse applications is possible. The use of additives such as EPDM and cork in our final products assures our market position and our future. This guarantees that we reach the desired application sectors with consistently high quality: Our product range spans from materials for insulation to slip prevention, from building protection to flooring for athletic purposes in places of human activity, applications for horse stables and artificial turf.

We currently employ 53 qualified staff and 4 trainees in a special job rotation system and thus assure product stability and reliable delivery. Since the company was founded individual product developments have been driven by cooperation with universities, research institutes and users. Innovative development, satisfaction of customer requirements and improved product quality are the most important components of our service.

Our goal is to search together for diverse applications and optimum problem solutions in YOUR interest and in the interest of the environment.

Quality

– Product properties guaranteed –

The manufacture of our baled materials relies on lean and automated production processes that are constantly monitored by our quality assurance personnel. As a DIN EN ISO 9001 certified operation our improvement process is supported by constant optimisation and development in order to manufacture our products with consistent and high quality.

The production of our most important raw material (rubber granulate) is performed using the most modern granulation, sifting and sorting technology, regardless of particle size. Our rubber raw input is obtained from recycled old tyres. Thus PVP Triptis GmbH makes an important contribution to sustainability and conservation of natural resources.

We are well aware of our obligations under the REACH EG/1907/2006 regulations directive applicable to secondary raw material producers. Pre-registration required by Art. 2 Sec. 7d is performed in accordance with the mandated schedule.

Technlogy

The ecological use of old tyres does not end when they are shredded. Using the most modern granulation, sifting and sorting technology, a clean rubber granulate can be produced for refining. Our technology is so flexible that the customer can specify the desired distribution of particle size.

In a second stage, the rubber granulate is bonded with a special recipe into large shaped pieces using a new handling process. Then these shaped pieces are shaved and made into baled materials or plates depending on the customer’s request.

Our company uses an integrated management system as defined in DIN EN ISO 9001:2008 for continuous improvement of processes and procedures. As a waste disposal firm, we naturally comply with the environmental management system as defined in DIN EN ISO 14001:2005.

Product

Using old tyres as the raw material means environment-friendly resource use in terms of the Closed-loop Recycling Management Act (Kreislaufwirtschaftsabfallgesetzes). The granulate, rubber mats and shaped pieces produced constitute a high-quality final product and provide our customers decisive market advantages.

Our expertise and our competence guarantee high quality. We offer development and application advice assist our customers in every stage of the decision.

There is still no end to the possible applications for our products. We are constantly finding new uses – we are engaged in constant development.

Innovation

Product development drives our company. Our products are constantly improved and advanced through intensive cooperation with reliable partners. New, innovative products are realised systematically for the market in close cooperation with scientific research institutions.

Our quality and management system monitors the high quality demands of our customers. Our aim is to work together with you to find diverse applications and at the same time optimum solutions that reflect your interests and benefit the environment.

Mit über zehnjähriger Erfahrung in der Entwicklung, Herstellung und Installation hochwertiger Produkte aus Gummigranulat, zählt die PVP Triptis GmbH zu den Spezialisten der Branche. Als erfolgreiches und weltweit tätiges Unternehmen, mit aktuell 65 Mitarbeitern, bieten wir unseren Kunden maßgeschneiderte Lösungen aus Gummi – MADE IN GERMANY. Durch aktuelle technische Entwicklungen gewährleistet unsere hochmoderne Produktion, dass alle unsere Produkte den strengen Qualitäts- und Umweltanforderungen der EU entsprechen. Wir erfüllen die höchsten Qualitätsstandards nach DIN EN ISO 9001: 2008, DIN EN ISO 14001:2009 und DIN EN ISO 50001:2011.

Wir Suchen:

Mitarbeiter im Vertriebsinnendienst (M/W)

Die Position umfasst:

- Betreuung eines definierten Kundenportfolios (vorwiegend englischsprachig)

- Arbeit mit ERP-System

- Erstellung von Angebotskalkulationen

- Angebotsbearbeitung

- Auftragsbearbeitung bis hin zur Rechnungslegung

- Erstellen von Außenwirtschaftsdokumenten

- Internationale Projektbetreuung

- Abrechnung Auslandsprojekte

- Eigenständige Betreuung einer einzelnen Produktpalette

- Ansprechpartner für englischsprachigen Außendienstler

Ihre Qualifikationen sind:

- Erfolgreich abgeschlossenes Studium im Bereich Betriebswirtschaft oder eine adäquate Fachrichtung

- Alternativ eine abgeschlossenen kaufmännische Ausbildung mit mehrjähriger Berufserfahrung im Bereich Vertrieb (Export)

- Fließende Englischkenntnisse in Wort und Schrift

- Gute PC-Kenntnisse im Umgang mit MS-Office

- Organisationstalent und Verantwortungsbewusstsein

- Flexibles Reagieren auf unterschiedliche Anforderungen

- Sehr gute kommunikative Fähigkeiten, kompetentes, überzeugendes Auftreten sowie zielorientiertes und eigeninitatives Handeln

Die Stelle ist zunächst im Rahmen einer Elternzeitvertretung befristet für 1 Jahr (bis 30. Juni 2016) zu besetzen. Die Möglichkeit der anschließenden Übernahme ist gegeben.

Die Einstellung soll spätestens zum 01. Februar 2015 erfolgen, ein früherer Eintrittstermin wäre wünschenswert, damit eine fundierte Einarbeitung gewährleistet werden kann.

Ihre aussagekräftigen Bewerbungsunterlagen mit möglichen Eintrittstermin senden Sie bitte schriftlich oder per E-Mail. Wir freuen uns auf Ihre Bewerbung!

Für Fragen stehen wir Ihnen gern zur Verfügung.

PVP Triptis GmbH

Frau Carina Ludwig

Im Bresselsholze 11

07819 Triptis

Tel.: +49 36482/ 88-770

E-Mail: carina.ludwig@pvp-gummi.de